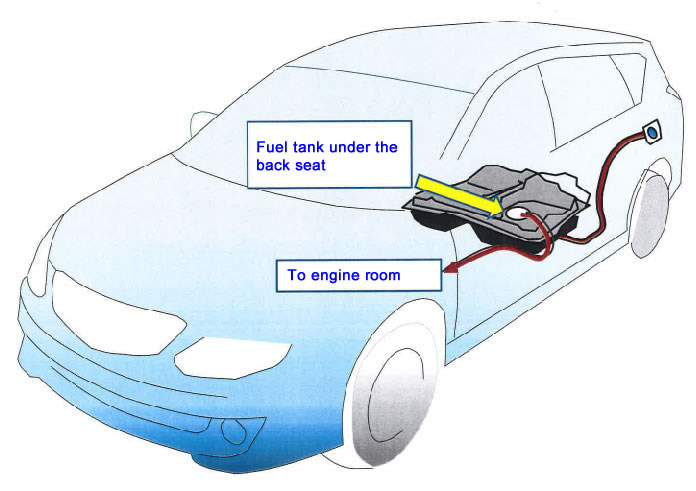

Fuel system parts

Fuel unit parts

|

Various insert molded products

|

Bobbins and sealing solenoid parts

|

|

|

Main factory - Mainly between 7t to 130t

Takasaki factory - Wide range of between 150t to 300t

Second class molding professional - 3 certified professionals

Main factory |

Takasaki factory |

Room temperature is maintained at 23 degrees C and humidity below 50%, to keep an environment for accurate measurements at all times. Precise measurement checks are possible using various measuring instruments.

Co-ordinate measuring machines (CMM) |

Contracer |

Circularity measuring instrument |

Image measuring instrument |

Regularly conduct maintenance, consider and order new molds, review and fix existing molds. Quick response is possible due to coordination with outside mold-manufacturing subcontractors.

|